Blue Stuff Mold 4 Bars – Reusable Thermoplastic for Molding

🔷 Blue Stuff Mold 4 Bars

Reusable Thermoplastic Moulding Material | Green Stuff World

🔄 Revolutionary Reusable Mould Making System

Blue Stuff Mold is an innovative thermoplastic material that transforms mould making into a simple, repeatable process. Just heat in hot water for 3 minutes, press onto any object, and within minutes you have a high-resolution reusable mould. This 4-bar pack provides approximately 24g total material for multiple projects - perfect for duplicating miniature parts, creating conversion pieces, copying details and producing custom components without expensive silicone or complex chemistry.

🔥 Game-Changing Features

Never buy moulding material again - reheat and remould hundreds of times without degradation or loss of detail quality.

No mixing, no measuring, no curing time - simply immerse in hot water until soft, then create instant moulds.

Captures microscopic details, fine textures and intricate surface features - perfect for miniature weapons and delicate components.

Works with epoxy putty, polyester resin, acrylic resin, green stuff, milliput and most casting materials - nothing sticks permanently.

🎯 Essential Applications

- Miniature Duplication - copy Warhammer weapons, duplicate small parts, create identical shoulder pads and accessories

- Conversion Components - replicate custom details, make matching sets of unique elements, mass-produce conversion bits

- Terrain & Scenery - duplicate bricks, stones, architectural details, create repeating texture patterns for bases and dioramas

- Jewellery Production - cast multiple copies of designs, create matching earring pairs, produce pendant duplicates

- Prototype Testing - quickly copy designs for client approval, create test castings, evaluate modifications

- Restoration Work - replicate broken or missing miniature parts, restore vintage models, repair damaged components

- Press Moulds - create texture stamps, embossing tools, decorative pattern makers for clay and putty

- Small Production Runs - produce limited edition pieces, convention exclusives, small batch components

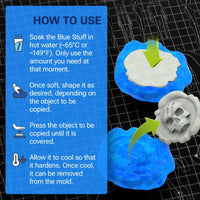

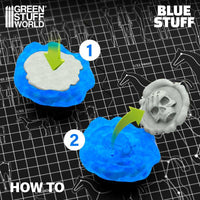

💡 Step-by-Step Usage Guide

🔹 Step 1 - Heat: Place bars in hot water (70-80°C) for approximately 3 minutes until completely soft and translucent

🔹 Step 2 - Shape: Remove from water, quickly dry, then press firmly onto object to capture all surface details

🔹 Step 3 - Cool: Hold in position for 2-3 minutes while material cools and hardens around the master

🔹 Step 4 - Cast: Fill mould with chosen material - epoxy putty, resin, green stuff or other casting medium

🔹 Step 5 - Demould: Wait for material to cure, then flex mould gently to release perfect duplicate

🔹 Step 6 - Reuse: Reheat mould in hot water to soften and create completely different mould - infinite possibilities

⚖️ Blue Stuff vs Silicone Moulds

💡 Pro Tip: Use Blue Stuff for quick tests and simple parts, silicone for complex production moulds

🎨 Pro Techniques & Tips

🎯 Perfect For These Hobbyists

✨ Key Advantages

⚠️ Important Notes

🔸 Temperature: Water must be hot (70-80°C) but not boiling - boiling water can damage material structure

🔸 Undercuts: Best for simple shapes - complex undercuts may require two-part mould techniques

🔸 Working Time: Material remains workable for 1-2 minutes after removal from water - work quickly

🔸 Lifespan: With proper use, bars can be reheated hundreds of times without performance loss

🏆 The Mould Making Revolution

Transform your hobby with infinitely reusable moulding technology - duplicate, restore and create like never before

Our brands